HOLDEN FX 48-215 Sedan and Utility 1948-1953 Comprehensive Workshop Service Manual | PDF Download

This manual is suitable for the following Holden models:

- Holden FX 48-215 Sedan

- Holden FX 50-2106 Ute

Please note: This manual covers all Holden models from 1948-1963.

Below is a very comprehensive list of topics covered in this Holden manual:

- General Specification

- General Lubrication

- Engine Lubrication

- Water Pump

- Generator

- Distributor

- Gear Shift

- Clutch

- Clutch Linkage

- Clutch and Brake Pedals

- Rear Axle

- Gearbox

- Steering gear

- Universal Joints

- Front Wheel bearings

- Rear Wheel bearings

- Spring Shackles

- Shock Absorbers

- Body Lubrication

- Body Frame

- General Description

- Front Sub-frame Assembly

- Doors

- Interior handles

- Trim linings

- Hinges

- Check

- Alignment

- Division channel

- Hold open device

- Rear door gravel shield

- Glass run channels

- Exterior handles and safety lock

- Locks

- Window regulator

- Door ventilator

- Lock striker plate

- Door removal

- Glass Replacement

- Windshield glass

- Rear window glass

- Front & rear door glass

- Front door ventilator glass

- Rear door quarter glass

- Weather and Dust Seals

- Door opening weather seal

- Door opening dust seal

- Cowl ventilator

- Windshield Wiper

- Trunk compartment lid

- Lid hinge

- Seats

- Construction

- Front seat

- Rear seat

- Seat springs

- Front seat adjuster

- Trim

- Door lining

- Head lining

- Seats

- Body electrical wiring

- Body lubrication

- Body & sub-frame alignment

- Rectification of body distortion

- Body shell & sub-frame parts replacement

- Solder loading

- Care & cleaning upholstery

- Body Sheet Metal

- Engine hood

- Hinges

- Adjustment

- Lock plate latch control & adjustment

- Alignment with top of radiator grille

- Grille

- Removal

- Installation

- Lower baffle assembly

- Removal

- Installation

- Front fenders

- Removal

- Installation

- Front fender alignment

- Rear fenders

- Rear fender alignment

- Engine hood

- Air Cleaner

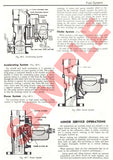

- Shock Absorbers

- Description

- Minor service operations

- Filling shock absorbers

- Checking fluid leaks

- Testing shock absorber operation

- Replacement of relief valves

- Shock absorber links

- Major service operations

- Replacement of shock absorber parts

- Front shock absorbers

- Rear shock absorbers

- Diagnosis chart

- Specifications

- Replacement of shock absorber parts

- Front Suspension

- General description

- Minor service operations and adjustments

- Cross member mountings

- Front wheel hubs and bearings

- Front wheel bearing adjustment

- Steering linkage

- Steering idler arm

- Steering connecting rod

- Tie rods and tie rod ball sockets

- Stabilizer bar

- Front suspension alignment

- Description

- Camber

- Caster

- King pin inclination

- Toe in

- Steering geometry (toe in on turns)

- Checking and adjusting alignment

- Checking caster and camber

- Adjusting caster and camber

- Checking king pin inclination

- Adjusting wheels to straight ahead position

- Adjusting toe in

- Checking steering geometry

- Major service repair operations

- Front suspension unit

- Front spring

- Lower control arm outer bolt and bushing

- Lower control arm and/or shaft

- Upper control arm outer bolt

- Upper control arm and/or shaft

- King pin bushings

- Diagnosis guide

- Special service tools

- Specifications

- Rear Axle

- Description

- Rear axle shafts and bearings

- Periodic service

- Axle bearings

- Differential

- Minor service operations

- Rear universal joint flang or pinion oil seal

- Rear axle shaft and bearing

- Axle oil seal

- Major service operations

- Differential carrier assembly

- Removal

- Inspection of differential before disassembly

- Complete disassembly

- Cleaning and inspection of differential parts

- Pinion bearing pre-load and pinion location

- Pre-load adjustment of new pinion bearings

- Assembly

- Installation

- Rear axle housing assembly

- Removal

- Disassembly

- Assembly

- Installation

- Diagnosis of rear axle noises

- Description

- Rear Suspension

- Description

- Rear spring mountings

- Rear spring seats

- Rear springs

- Specifications

- Propeller Shaft and universal Joints

- Description

- Removal – Propeller shaft

- Inspection and lubrication of universal joints

- Installation – propeller shaft

- Front propeller shaft housing

- Checking oil leak at front yoke

- Diagnosis of propeller shaft and universal joint faults

- Specifications

- Description

- Brakes

- Description

- Master cylinder

- Wheel cylinder

- Sequence of events during operation

- Handbrake

- Hydraulic Brake Fluid

- Preventative Maintenance

- Minor service operations

- Bleeding the hydraulic system

- Brake master cylinder push rod adjustment

- Brake shoe adjustment

- Handbrake adjustment

- Handbrake pull rod assembly

- Handbrake front cable and conduit assembly

- Brake pedal assembly

- Stop light switch

- Major service operations

- Brake shoe replacement

- Handbrake actualating lever adjustment

- Brake drums

- Master cylinder repair/replacement

- Wheel cylinder repair/replacement

- Diagnosis guide

- Specifications

- Description

- Engine Assembly

- General description

- Intake and exhaust manifolds

- Engine lubrication

- Engine ventilation

- Minor service operations

- Engine tune-up

- Valve adjustment

- Valve timing check

- Cylinder head and valve conditioning

- Oil pump

- Timing gear cover oil seal

- Camshaft and/or engine front cover plate

- Engine mountings

- Major service operations

- Engine removal, disassembly, inspection

- Repairs to engine parts

- Cylinder conditioning

- Cylinder boring

- Cylinder honing and piston fitting

- Piston pin and bushing fitting

- Connecting rod alignment, piston and connecting rod assembly

- Piston ring fitting

- Camshaft, camshaft bearings and timing gear

- Crankshaft, crankshaft bearings and timing gear

- Flywheel and ring gear

- Cylinder head and valve gear

- Oil pump

- Timing gear cover oil seal

- Engine assembly and installation

- Diagnosis chart

- General description

- Fuel System

- Carburettor

- Description

- Operation

- Minor service operations

- Idle adjustments

- Checking and adjusting fuel level

- Accelerator pump stroke adjustment

- Fuel consumption tests

- Major service operations

- Carburettor removal, disassembly, inspection, installation

- Air cleaner

- Service operations

- Fuel and vacuum pump

- Description

- Operation

- Minor service operations

- Testing fuel pump

- Period service check

- Testing vacuum pump

- Major service operations

- Removal, disassembly, inspection installation

- Diagnosis chart

- Carburettor

- Fuel pump

- Vacuum pump

- Carburettor

- Cooling System

- General description

- Water pump

- Vehicle operation in cold regions

- Cooling system inhibitors

- Minor service operations

- Draining and flushing the system

- Fan belt adjustment

- Thermostat

- Radiator cap

- Major service operations

- Water pump, remove repair/replace, install

- Radiator Remove. Install

- Diagnosis chart

- Special tools

- Specifications

- General description

- Clutch

- General description

- Minor service operations

- Break in of new driven plate facings

- Clutch control adjustments

- Master cylinder push rod adjustment

- Clutch fork operating rod adjustment

- Clutch pedal return (over centre) spring adjustment

- Clutch pedal assembly

- Hydraulic fluid

- Bleeding the hydraulic system

- Major service operations

- Clutch actuating cylinder overhaul

- Clutch master cylinder overhaul

- Clutch assembly, removal, inspect/replace, assemble

- Diagnosis chart

- Special tools

- Specifications

- Engine Special Tools

- Engine Specifications

- Transmission

- General description

- Minor service operations

- Gearshift linkage adjustment

- Gearshift linkage overhaul

- Transverse selector shaft oil seal replacement

- Selector lever shaft housing and/or oil seal replacement

- Speedometer gear replacement

- Major service operations

- Transmission removal, dismantle, inspect, replace, assemble, install

- Diagnosis guide

- Special tools

- Specifications

- Steering System

- General description

- Minor service operations

- Steering wheel

- Steering gear adjustment

- Steering shaft upper bearing replacement

- Major service operations

- Sector shaft end play adjustment

- Steering gear assembly overhaul

- Diagnosis chart

- Specifications

- Electrical System

- Wiring diagrams

- Battery

- Diagnosis guide

- Torque Wrench Specifications

File Format: PDF

Language: English

Print: Print the complete manual or just the pages you require

Bookmarked: Bookmarked for easy navigation

Requirements: We recommend using Adobe PDF Reader for best results

Device: We recommend downloading to a PC or Laptop or visit our Download Help Page for further information regarding Smart Devices

Images are Copyright©Car Manuals Direct and are used for promotional purposes only.

Copyright©Car Manuals Direct 2018

HOLDEN FX 48-215 HISTORY

Holden FX 48-215

Australia’s first mass produced car, the Holden 48/215 (FX) was launched on the 29th November 1948. The Holden was originally offered in one body style, a 4 door sedan known as the 48/215. About two and a half years later in January 1951, the Utility model was launched. This was known as the 50/2106 model.

The original sedan was offered in four different exterior colours, Black, Gawler Cream, Seine Blue and Convoy Grey. Interior trim was either Grey woollen Bedford cloth or red leather.

When released, the cost of the new Holden 48/215 was £734 ($1469). The Utility was priced at £843 ($1686). From November 1948 to October 1953, there were 120,402 Holden’s manufactured.

Although General Motors Holden officially called the models 48/215 (Sedan) and 50/2106 (Utility) they were commonly known by the public and motor trade as the Holden FX. It is rumoured this designation came about in the mid 1950’s from Melbourne used car dealers wanting to differentiate the early cars from the later FJ Series.

Source: Heart of the Lion – The 50 Year History of Australia’s Holden by John Wright & 60 Years of Holden by Terry Beddington

All images and information shown are Copyright © Car Manuals Direct. Images used for promotional purposes only. Not included in Manual.